Ok Folks...Here is the skinny. I put in a brand new clutch, pressure plate, throw-out bearing, machined the flywheel, yadda, yadda...about a year ago. Just put in a new Dave T-Bow Mallory Unilite distributor...the old girl runs like a scalded dog. Boy am I happy!

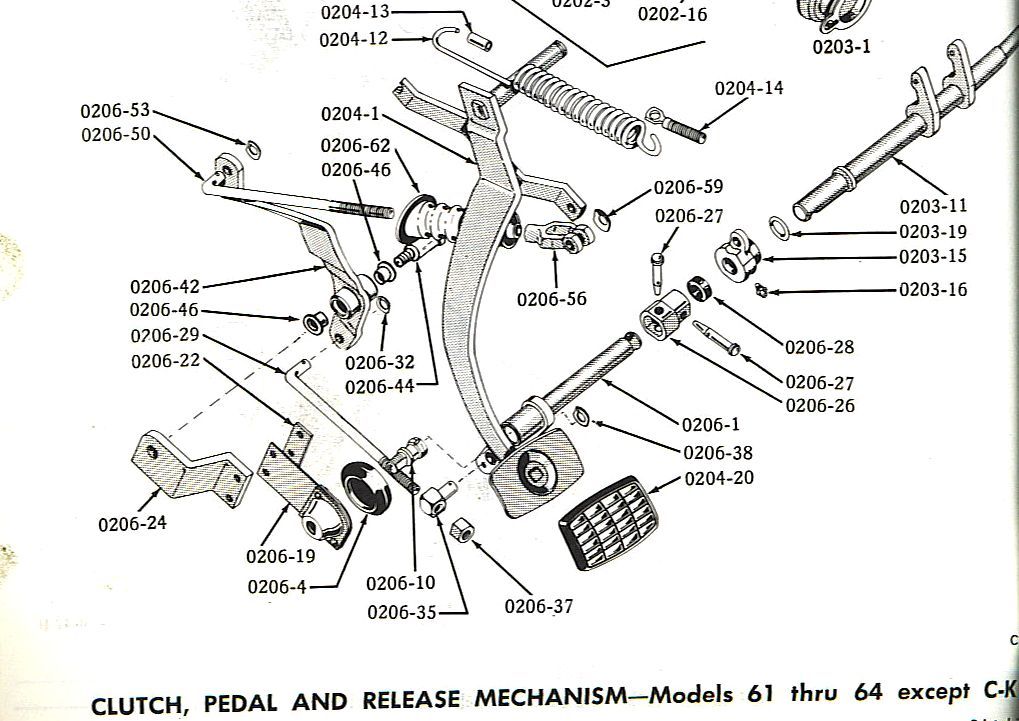

BUT...I have been losing my clutch adjustment. In the last month I have readjusted the linkage 3 times to eliminate "dragging" to the point where I have to shut the car off to put it in reverse. As of this morning's adjustment it works fine, again, but now I have NO free-play at the top of the pedal.

Is my analysis correct in that I believe the throw-out bearing "fork" is slipping on the bellhousing shaft? If so, how do I know where to spin it so it is in the correct radial position prior to welding it?

Any ideas would be greatly appreciated.

D

BUT...I have been losing my clutch adjustment. In the last month I have readjusted the linkage 3 times to eliminate "dragging" to the point where I have to shut the car off to put it in reverse. As of this morning's adjustment it works fine, again, but now I have NO free-play at the top of the pedal.

Is my analysis correct in that I believe the throw-out bearing "fork" is slipping on the bellhousing shaft? If so, how do I know where to spin it so it is in the correct radial position prior to welding it?

Any ideas would be greatly appreciated.

D

BP

BP  We've got to quit saying,

We've got to quit saying,

BP

BP

Comment