Did yawl catch it last week when I stuck a size-twelve Red Wing in my mouth? Yeah, I tried to blame it all on Evelynn Wood, but now I'm back to face the music in a blatant attempt at self-redemption.

The subject was belts, and how best to measure for fresh ones. Granted, it isn't usually necessary to achieve deadly accuracy when measuring for belts, but sometimes things get a little tight in early engine compartments. Some of us like to stuff that proverbial ten pounds of poo in a five-pound bag. Yawl know who you are.

Now before I dig in deeper; I should go on and say that I've been playin' with Studes (and some other brands) long enough to know better, but for whatever reason; I didn't know how to properly measure for belts until recently. The last time I tried, (about three months ago) I fashioned a mock-belt from wire and took it to the parts guy. Well, that didn't work, so I went back the next day, and the next day, and the next day, until I finally just lucked out. Now some of yawl are laughin' at me, and that's arright. I have a good friend who is what I'd call a "real mechanic" and he laughed a little too -- then he shared his measuring method with me. "Keep some old belts around. You can always use one that's too long, just cut to fit -- there's your sample." Now as Tom pointed out here last week; someone's got to hold the sample-belt together while someone else sneeks up and measures it. That's about the only drawback to the 'cut to fit' method -- it takes four hands.

I like to splatter paint around every now and then, so I've got the high-quality green maskin' tape from 3M on the shelf at all times. It'll adhere fairly well to a belt if wrapped tight enough, but Tom also pointed out that slippage might be difficult to see beneath tape. Then he suggested staples as I recall, this sounded good so today I thought I'd give his method a try. "Where's the T-50s? I know they're on this shelf somewhere... Maybe if I get some other stuff out of the way... Let's see... Move all these zip-ties... Now move all this shrink-tube and... Doh! SHRINK-TUBE!" The 'hot tip' was right in front of my nose.

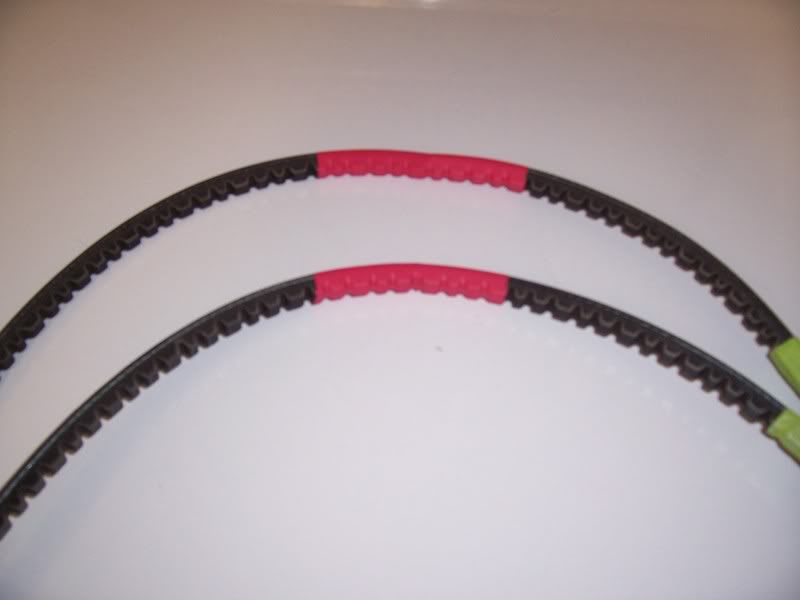

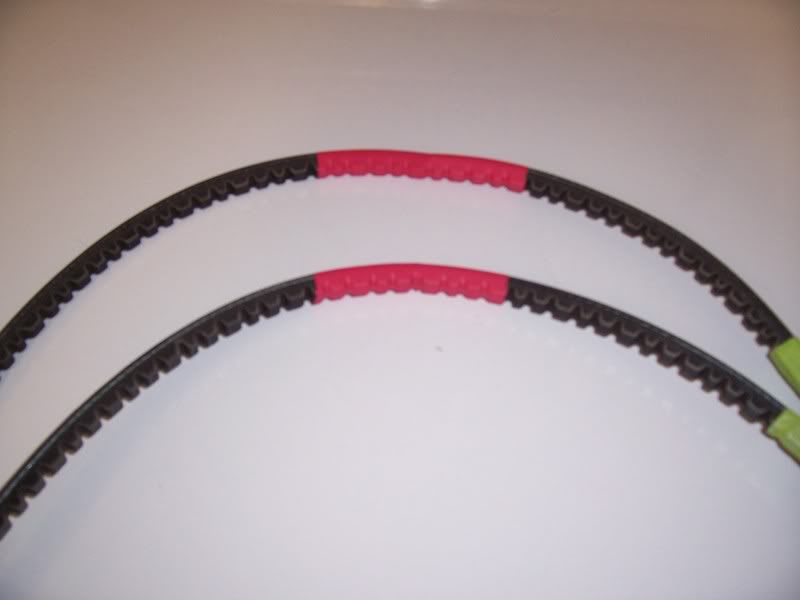

This works like a Studebaker Champ! Slip it in, hold it toghther, (single-handedly) while using your remaing free-hand to pull the trigger on the heat-gun. This works exceptionally well with the late-model knobby-tread belts. Ours did not slip. Oh, now you're thinkin' this won't work on smooth belts, right? Carve some grooves in the ends -- now you have the knobby-tread design workin' for you too.

This simple accedental discovery made my day go a little easier. Hopefully, it'll help someone else down the road.

Now where's that 'spell-czech' button? There's gotta be one around here somewhere... RR

Faster than a rusting bullet... Gopher Grove, CA

The subject was belts, and how best to measure for fresh ones. Granted, it isn't usually necessary to achieve deadly accuracy when measuring for belts, but sometimes things get a little tight in early engine compartments. Some of us like to stuff that proverbial ten pounds of poo in a five-pound bag. Yawl know who you are.

Now before I dig in deeper; I should go on and say that I've been playin' with Studes (and some other brands) long enough to know better, but for whatever reason; I didn't know how to properly measure for belts until recently. The last time I tried, (about three months ago) I fashioned a mock-belt from wire and took it to the parts guy. Well, that didn't work, so I went back the next day, and the next day, and the next day, until I finally just lucked out. Now some of yawl are laughin' at me, and that's arright. I have a good friend who is what I'd call a "real mechanic" and he laughed a little too -- then he shared his measuring method with me. "Keep some old belts around. You can always use one that's too long, just cut to fit -- there's your sample." Now as Tom pointed out here last week; someone's got to hold the sample-belt together while someone else sneeks up and measures it. That's about the only drawback to the 'cut to fit' method -- it takes four hands.

I like to splatter paint around every now and then, so I've got the high-quality green maskin' tape from 3M on the shelf at all times. It'll adhere fairly well to a belt if wrapped tight enough, but Tom also pointed out that slippage might be difficult to see beneath tape. Then he suggested staples as I recall, this sounded good so today I thought I'd give his method a try. "Where's the T-50s? I know they're on this shelf somewhere... Maybe if I get some other stuff out of the way... Let's see... Move all these zip-ties... Now move all this shrink-tube and... Doh! SHRINK-TUBE!" The 'hot tip' was right in front of my nose.

This works like a Studebaker Champ! Slip it in, hold it toghther, (single-handedly) while using your remaing free-hand to pull the trigger on the heat-gun. This works exceptionally well with the late-model knobby-tread belts. Ours did not slip. Oh, now you're thinkin' this won't work on smooth belts, right? Carve some grooves in the ends -- now you have the knobby-tread design workin' for you too.

This simple accedental discovery made my day go a little easier. Hopefully, it'll help someone else down the road.

Now where's that 'spell-czech' button? There's gotta be one around here somewhere... RR

Faster than a rusting bullet... Gopher Grove, CA

Not that I've ever used a shrink tube in my life, nor do I know where to get them. FLAPS? Now, where did I put that heat gun...

Not that I've ever used a shrink tube in my life, nor do I know where to get them. FLAPS? Now, where did I put that heat gun...

Comment