I'm not sure whether this is a rant or a whine.

I took a rip at dialing in the Avanti bellhousing Saturday. I got the bellhousing from Phil Harris and have to assume he sent me the correct part because we discussed the application extensively. The engine is on the frame and the bellhousing attached with the dowels in. I got a dial test indicator from a motorcycle gearhead friend. I didn't even need to use it, as you will soon see.

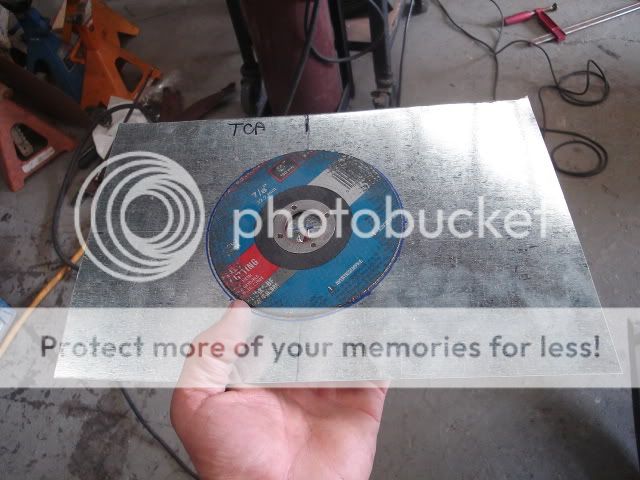

I have a generic clutch aligning tool that I inserted in the crankshaft and hoped to use as a mounting for the test indicator. The tool does not screw in, however, and only maintains its position by friction. Already I was foreseeing problems as there was a little play even when I jammed it in and it came loose easily. Even eyeballing it in its strongest position it looked off. Using a tape measure i measured that the clutch tool was sitting an eighth of an inch too low.

I tapped out the dowels, lifted the engine with wood blocks under the exhaust manifolds and tried to tap the bellhousing down. Upon re-measuring, I learned that it had gotten farther off. Now it was 3/16 too low.

But how can that be? The screws couldn't go into the screw holes if the parts were that far off. I wonder if the clutch isn't on right, thereby pushing the aligning tool off center, but that still presents the same conundrum -- how could the screw holes in the clutch match up if it's that far off?

Left to my own devices i would jack up the engine under the manifolds, remove the bellhousing, clutch and flywheel, and try to figure out some way to mount the dial test indicator in the crankshaft bolts, like the example on Bob Johnstone's web site. I would struggle with it for a day or two, then invite some friends over to help. They would have no idea what to do because there are only four people in the world who can actually do this and they don't live within four states of here. I would then throw the thing away and get a Ford 302, having had a flash of understanding of the beauty of brand X equipment -- you don't have to be a tool and die expert to put the friggin' thing together.

By the way, I am not attaching a stude transmission. It's going to be a t-5 out of a mustang. Somebody please make my day and tell me this means I don't have to worry about this little dial-in game.

Any thoughts you may have are appreciated.

Tom

I took a rip at dialing in the Avanti bellhousing Saturday. I got the bellhousing from Phil Harris and have to assume he sent me the correct part because we discussed the application extensively. The engine is on the frame and the bellhousing attached with the dowels in. I got a dial test indicator from a motorcycle gearhead friend. I didn't even need to use it, as you will soon see.

I have a generic clutch aligning tool that I inserted in the crankshaft and hoped to use as a mounting for the test indicator. The tool does not screw in, however, and only maintains its position by friction. Already I was foreseeing problems as there was a little play even when I jammed it in and it came loose easily. Even eyeballing it in its strongest position it looked off. Using a tape measure i measured that the clutch tool was sitting an eighth of an inch too low.

I tapped out the dowels, lifted the engine with wood blocks under the exhaust manifolds and tried to tap the bellhousing down. Upon re-measuring, I learned that it had gotten farther off. Now it was 3/16 too low.

But how can that be? The screws couldn't go into the screw holes if the parts were that far off. I wonder if the clutch isn't on right, thereby pushing the aligning tool off center, but that still presents the same conundrum -- how could the screw holes in the clutch match up if it's that far off?

Left to my own devices i would jack up the engine under the manifolds, remove the bellhousing, clutch and flywheel, and try to figure out some way to mount the dial test indicator in the crankshaft bolts, like the example on Bob Johnstone's web site. I would struggle with it for a day or two, then invite some friends over to help. They would have no idea what to do because there are only four people in the world who can actually do this and they don't live within four states of here. I would then throw the thing away and get a Ford 302, having had a flash of understanding of the beauty of brand X equipment -- you don't have to be a tool and die expert to put the friggin' thing together.

By the way, I am not attaching a stude transmission. It's going to be a t-5 out of a mustang. Somebody please make my day and tell me this means I don't have to worry about this little dial-in game.

Any thoughts you may have are appreciated.

Tom

Some day I'll have to, and I'm not looking forward to it; I don't do well with written instructions. If somebody showed me in person one time I'd have it down, but no one I know that has done this lives within a couple hundred miles of me

Some day I'll have to, and I'm not looking forward to it; I don't do well with written instructions. If somebody showed me in person one time I'd have it down, but no one I know that has done this lives within a couple hundred miles of me

]. I have seen a few apprentices launch expensive test indicators out of a milling machine when they thought it was in neutral. Also may want to add, Remove spark plugs to ease the rotation by hand. Neal

]. I have seen a few apprentices launch expensive test indicators out of a milling machine when they thought it was in neutral. Also may want to add, Remove spark plugs to ease the rotation by hand. Neal

Comment