The one part I was sure was good in my truck was the engine. It runs strong, doesn't smoke, doesn't leak (much), doesn't make any weird noises and has good oil pressure.

But while it's out it seemed smart to flush out the cooling jackets, put in new freeze plugs, clean it, reseal and paint it. Of course as long as the oil pan was off it also made sense to check the bearings, and it would give me a chance to try out Plastigage, which I've never used before.

Well... I still haven't used Plastigage.

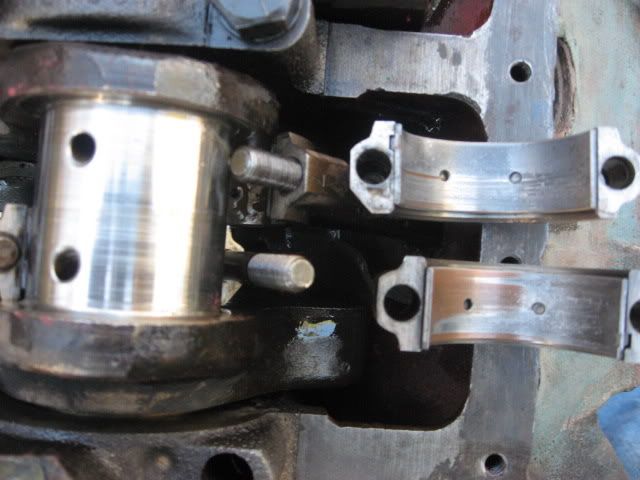

Couple of the worst rod bearings.

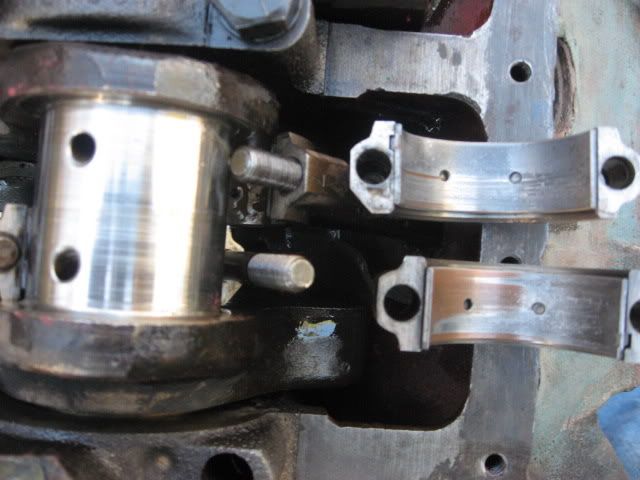

Worst of the mains.

Fortunately the crank seems OK except for some what looks like minor scoring on one of the rod journals.

I guess the right thing to do is to take the crank in and have it professionally cleaned and polished... I REALLY don't want to get it reground unless it's absolutely necessary.

Comments, suggestions, ideas?

If anyone wants to see all the pictures they are here.....

Thanks!

But while it's out it seemed smart to flush out the cooling jackets, put in new freeze plugs, clean it, reseal and paint it. Of course as long as the oil pan was off it also made sense to check the bearings, and it would give me a chance to try out Plastigage, which I've never used before.

Well... I still haven't used Plastigage.

Couple of the worst rod bearings.

Worst of the mains.

Fortunately the crank seems OK except for some what looks like minor scoring on one of the rod journals.

I guess the right thing to do is to take the crank in and have it professionally cleaned and polished... I REALLY don't want to get it reground unless it's absolutely necessary.

Comments, suggestions, ideas?

If anyone wants to see all the pictures they are here.....

Thanks!

Comment