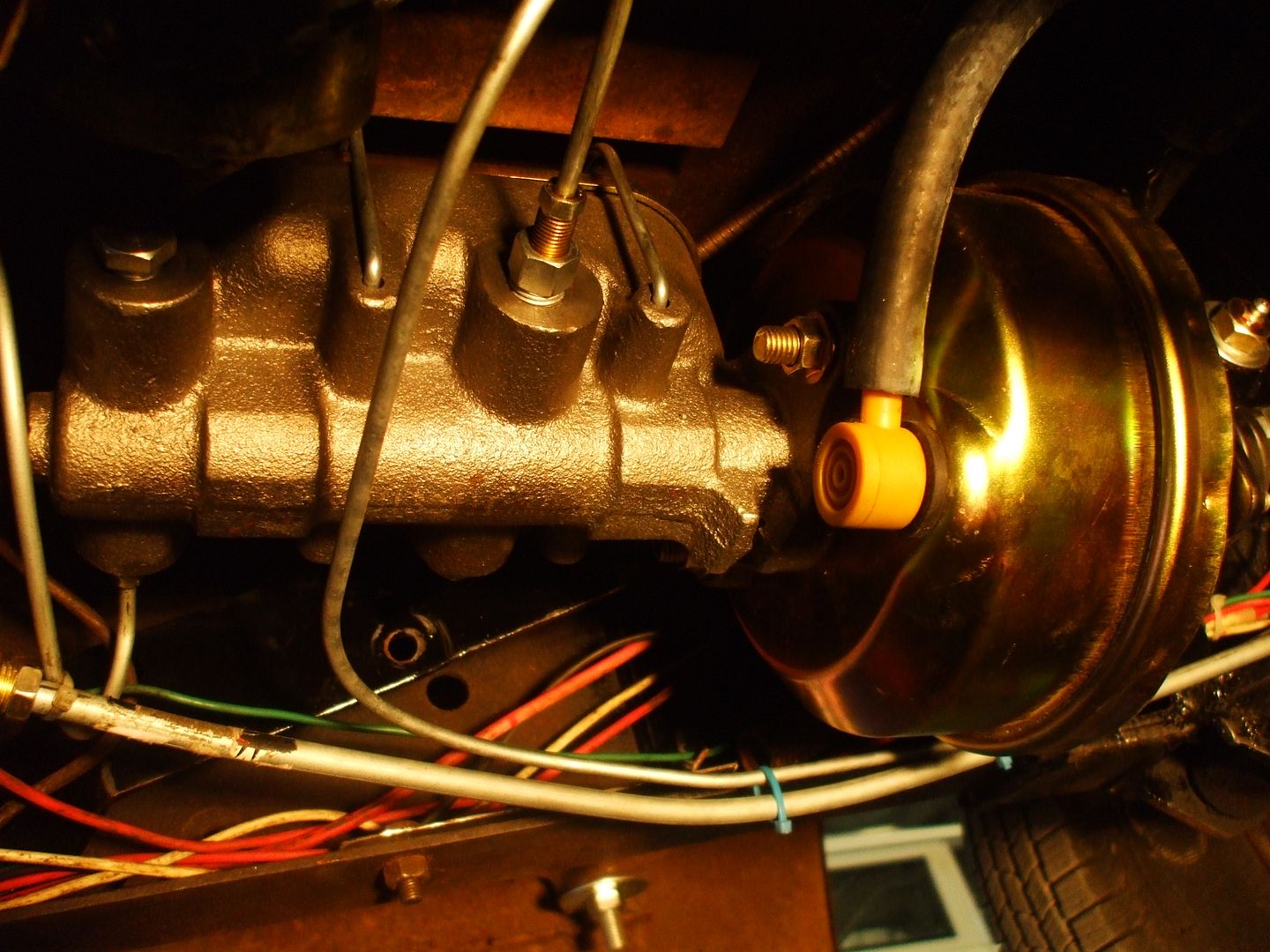

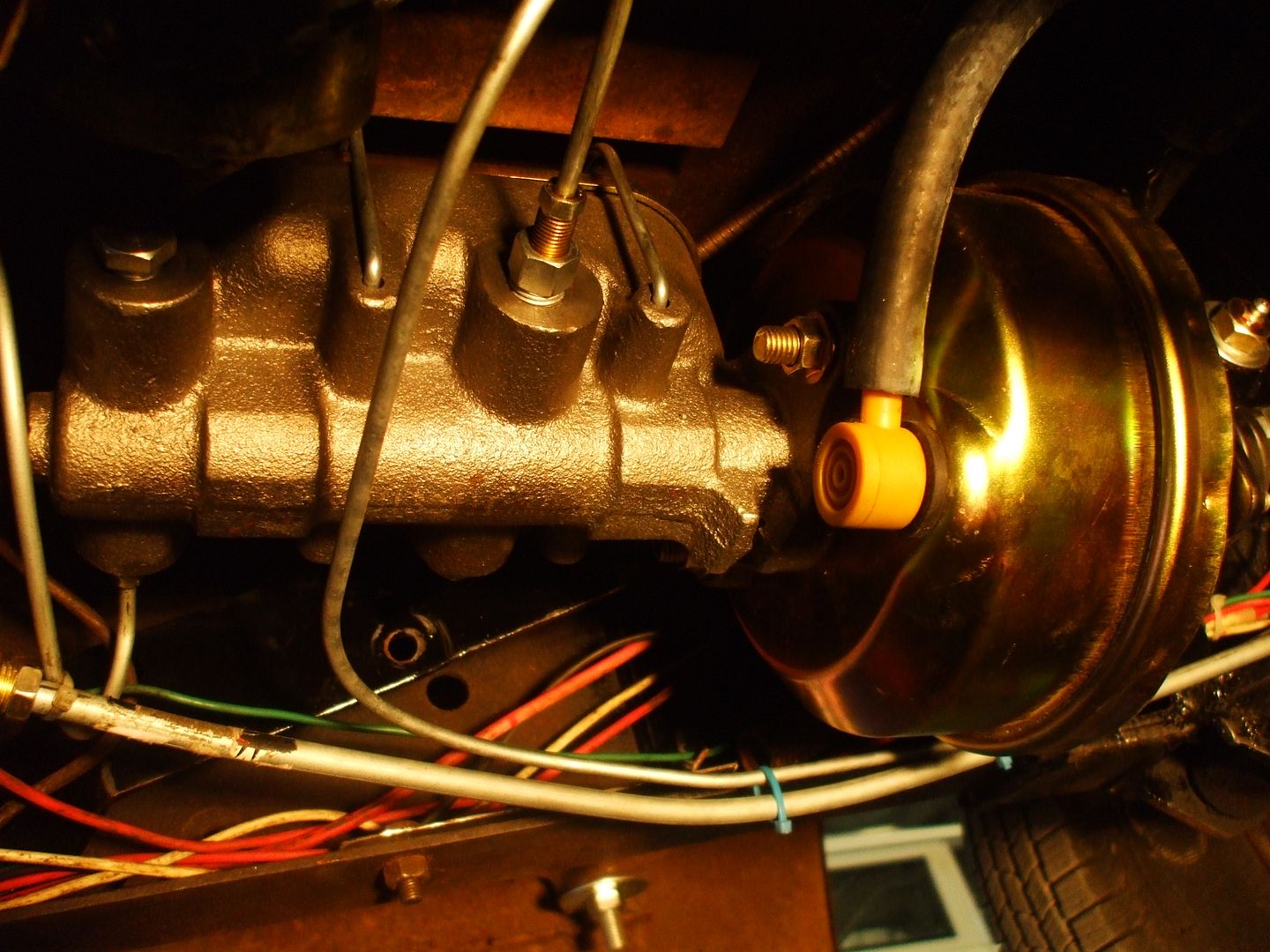

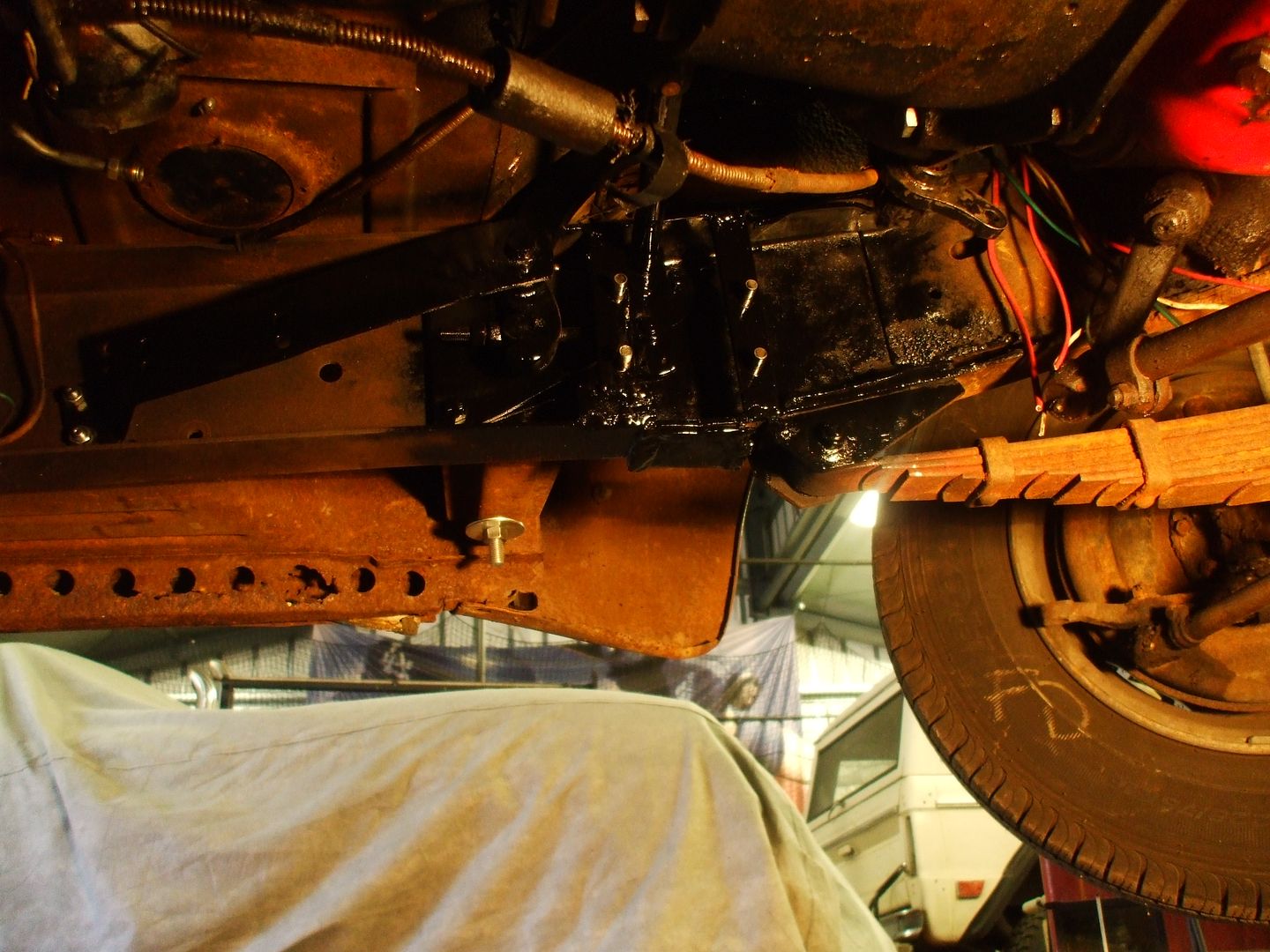

I recently installed a power brake unit with dual master cylinder on the 1952 Studebaker Camper that i sold last year. The new owner wanted to upgrade the brakes as he plans to have his family member use the truck. I will take the next few days to post the pictures with comments that show you just how easy this was. I was actually surprised that it wasn't a major ordeal. It took me 23 hours of fabricating and that was working at a leisurely pace. I will tell you that there were several pieces that I had to make twice. I am not a pro fabricator so I have to make a part and fit it in place and then see if it works. I will also share the part numbers and sources for the needed parts. I can tell you that the truck stops like a newer model truck with no lock up or other issues. The pedal effort is light but not scary. The pedal travel before you feel engagement is about 1". The owner took it for a test drive and didn't want to come home he was enjoying himself too much.

In keeping with making sure you understand the complete scope of this project I can tell you that there are two things that I would do differently on the next one. I would angle the master cylinder down at the back by a few degrees to give a little more clearance for the clutch linkage and master cylinder cap. We will also be changing the angle of the brake pedal as it is still a little too low compared to the clutch pedal. Just enough to make it uncomfortable on a long trip I think. We might take it on a trip before we make that change. Overall this is a great upgrade and highly recommended. I will probably be doing this to the 1947 truck that I will be working on this winter. I also have ordered the unit to be installed on my 1959 Silver Hawk that I am currently working on.

Tonight I will post some pictures of the completed unit'

Dan

That last picture was taken before the clutch return spring bracket was fabricated and the wiring had not been finished but you get the idea. tomorrow night I will list the parts that were used to make this happen.

In keeping with making sure you understand the complete scope of this project I can tell you that there are two things that I would do differently on the next one. I would angle the master cylinder down at the back by a few degrees to give a little more clearance for the clutch linkage and master cylinder cap. We will also be changing the angle of the brake pedal as it is still a little too low compared to the clutch pedal. Just enough to make it uncomfortable on a long trip I think. We might take it on a trip before we make that change. Overall this is a great upgrade and highly recommended. I will probably be doing this to the 1947 truck that I will be working on this winter. I also have ordered the unit to be installed on my 1959 Silver Hawk that I am currently working on.

Tonight I will post some pictures of the completed unit'

Dan

That last picture was taken before the clutch return spring bracket was fabricated and the wiring had not been finished but you get the idea. tomorrow night I will list the parts that were used to make this happen.

Comment