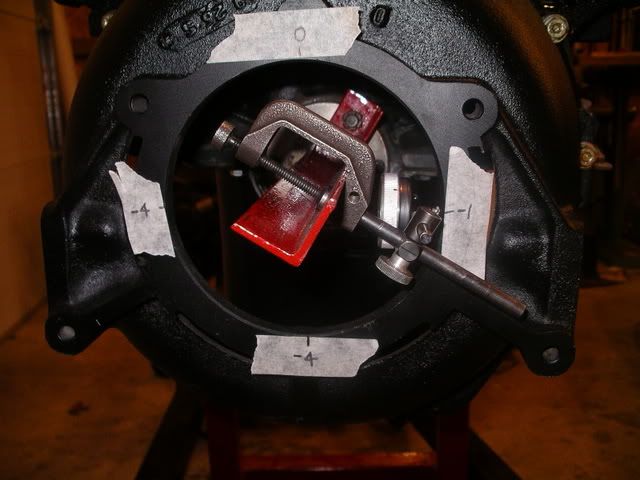

I've never dialed in a bell housing before but with a little advice, I successfully accomplished the procedure. I started out building a tool from Bob Johnstone's Avanti page and mounting it to the crank.

I pulled the existing dowel pins and mounted the bell housing just firmly with all the bolts to the block. I then Mounted the dial indicator to the new tool and set the reading about half way through the throw of the indicator then setting the reading to 0. This will allow a Positive and Negative reading.

You should know this is a two person procedure or you will be running back and forth, up and down a lot. My Son was turning the crank bolt while I was taping numbers to the quadrants at 12:00, 3:00, 6:00 and 9:00 o'clock positions

If 12:00 o'clock is dialed in to "0" and 6:00 o'clock is "8" the bell housing needs to shift .004 down splitting the difference between the two points

The indicator reads at 9:00 o'clock "2" and 3:00 o'clock reads "10" which is .008 between them and needs to be shifted .004 to the right.

The rubber mallet did not work for me and just bounced off no matter I hard I hit it so I got out the big gun and tapped it to the right with ease. Just a light tap

Check the reading again. I managed to bump it .004 to the right

Well I should have the bell housing on the horizontal pretty well centred. Dial it back to zero and check it.

Remark the tape to "0" and Move the crank to 3:00 o'clock

check the reading and mark the tape '2' I am now out .002 from 9:00 o'clock

Move to the Vertical. We know we are out .004 from the top so give it a bump down

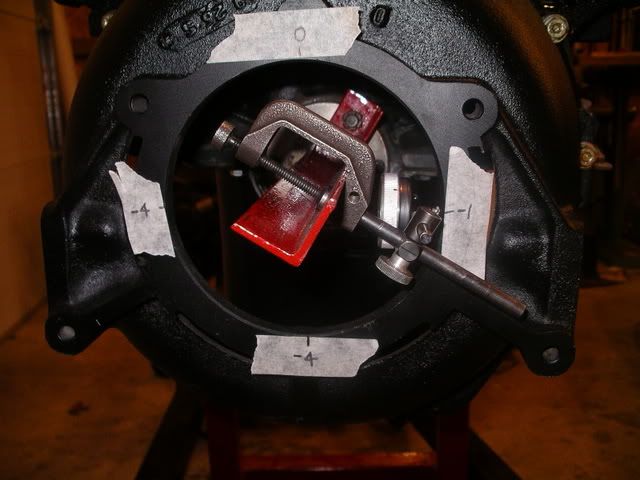

At this point I re-taped all quadrants and set the dial indicator at the 12 'clock position. After bumping I tightened the bell housing down Dialed in 12:00 o'clock to zero I took readings again.

'clock position. After bumping I tightened the bell housing down Dialed in 12:00 o'clock to zero I took readings again.

12:00 - '0' 3:00 - '-1' 6:00 - '-4' and 9:00 - '-4'

On the vertical I am out .004 and within tolerances on the horizontal I am out .003 and within tolerances too.

I checked it again and decided this was good enough. I located my 3/8 dowel pins I purchased at my local industrial supplier and a slightly smaller sized drill bit and re-drilled the existing 5/16" holes for the 3/8" dowels.

The entire process took my son and I about 2 hours last night to dial in the bell housing. It allow me to install Flex plate, torque converter, and transmission today

One thing in my mind remains unanswered, I have the Bell housing centered to the crank and there is no tolerances between the flex plate and the crank. but there seems to be tolerances between the torque converter and the flex plate. The manual uses a special "J- tool" I don't have the number right now but that "J series tool" aligns the torque converter to the flex plate by attaching to the Bell housing and to the torque converter then you turn the engine over twice and tighten the flex plate bolts.

I am thinking I could accomplish the same thing by mounting the transmission

I pulled the existing dowel pins and mounted the bell housing just firmly with all the bolts to the block. I then Mounted the dial indicator to the new tool and set the reading about half way through the throw of the indicator then setting the reading to 0. This will allow a Positive and Negative reading.

You should know this is a two person procedure or you will be running back and forth, up and down a lot. My Son was turning the crank bolt while I was taping numbers to the quadrants at 12:00, 3:00, 6:00 and 9:00 o'clock positions

If 12:00 o'clock is dialed in to "0" and 6:00 o'clock is "8" the bell housing needs to shift .004 down splitting the difference between the two points

The indicator reads at 9:00 o'clock "2" and 3:00 o'clock reads "10" which is .008 between them and needs to be shifted .004 to the right.

The rubber mallet did not work for me and just bounced off no matter I hard I hit it so I got out the big gun and tapped it to the right with ease. Just a light tap

Check the reading again. I managed to bump it .004 to the right

Well I should have the bell housing on the horizontal pretty well centred. Dial it back to zero and check it.

Remark the tape to "0" and Move the crank to 3:00 o'clock

check the reading and mark the tape '2' I am now out .002 from 9:00 o'clock

Move to the Vertical. We know we are out .004 from the top so give it a bump down

At this point I re-taped all quadrants and set the dial indicator at the 12

'clock position. After bumping I tightened the bell housing down Dialed in 12:00 o'clock to zero I took readings again.

'clock position. After bumping I tightened the bell housing down Dialed in 12:00 o'clock to zero I took readings again.12:00 - '0' 3:00 - '-1' 6:00 - '-4' and 9:00 - '-4'

On the vertical I am out .004 and within tolerances on the horizontal I am out .003 and within tolerances too.

I checked it again and decided this was good enough. I located my 3/8 dowel pins I purchased at my local industrial supplier and a slightly smaller sized drill bit and re-drilled the existing 5/16" holes for the 3/8" dowels.

The entire process took my son and I about 2 hours last night to dial in the bell housing. It allow me to install Flex plate, torque converter, and transmission today

One thing in my mind remains unanswered, I have the Bell housing centered to the crank and there is no tolerances between the flex plate and the crank. but there seems to be tolerances between the torque converter and the flex plate. The manual uses a special "J- tool" I don't have the number right now but that "J series tool" aligns the torque converter to the flex plate by attaching to the Bell housing and to the torque converter then you turn the engine over twice and tighten the flex plate bolts.

I am thinking I could accomplish the same thing by mounting the transmission

Comment