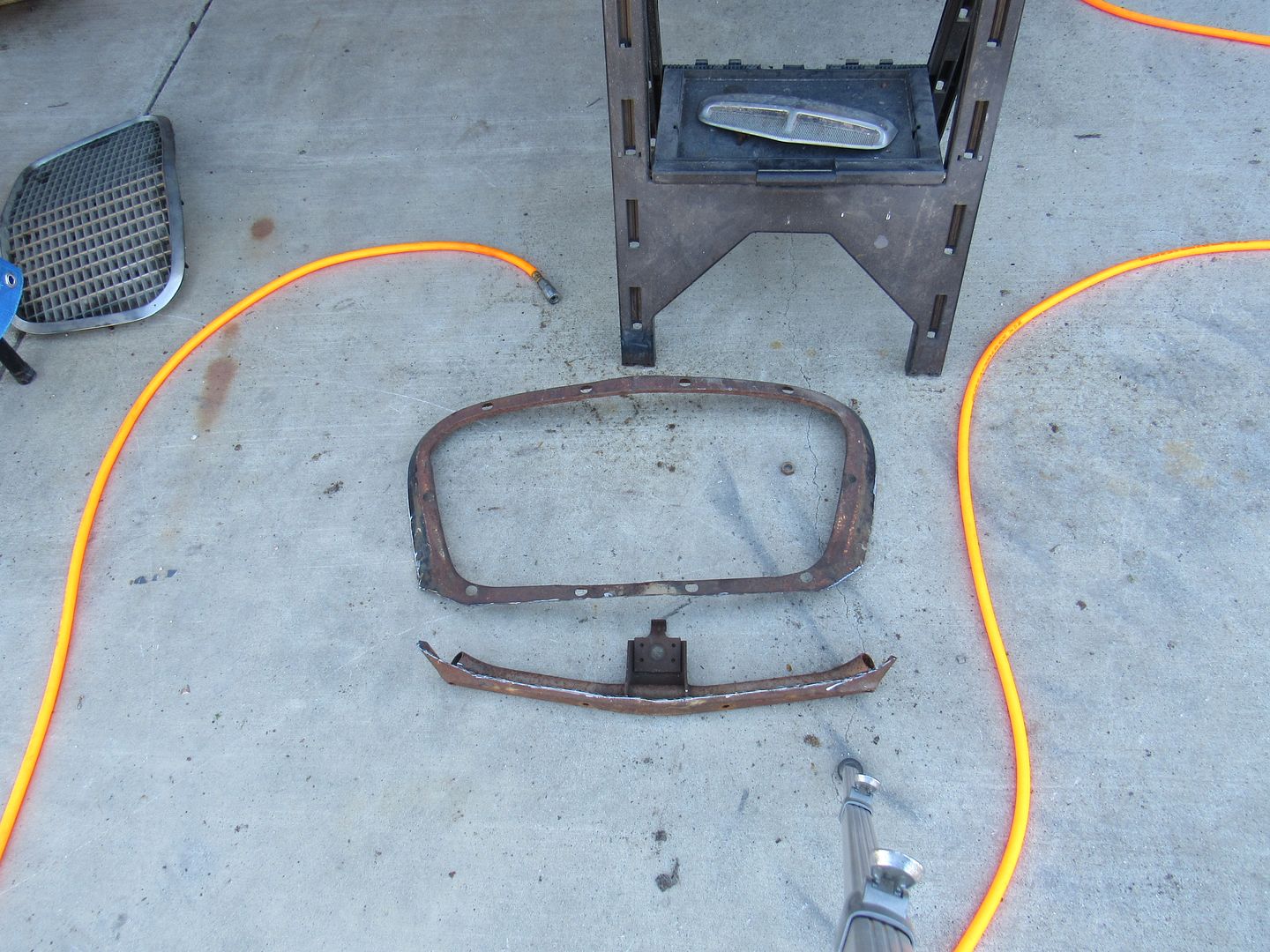

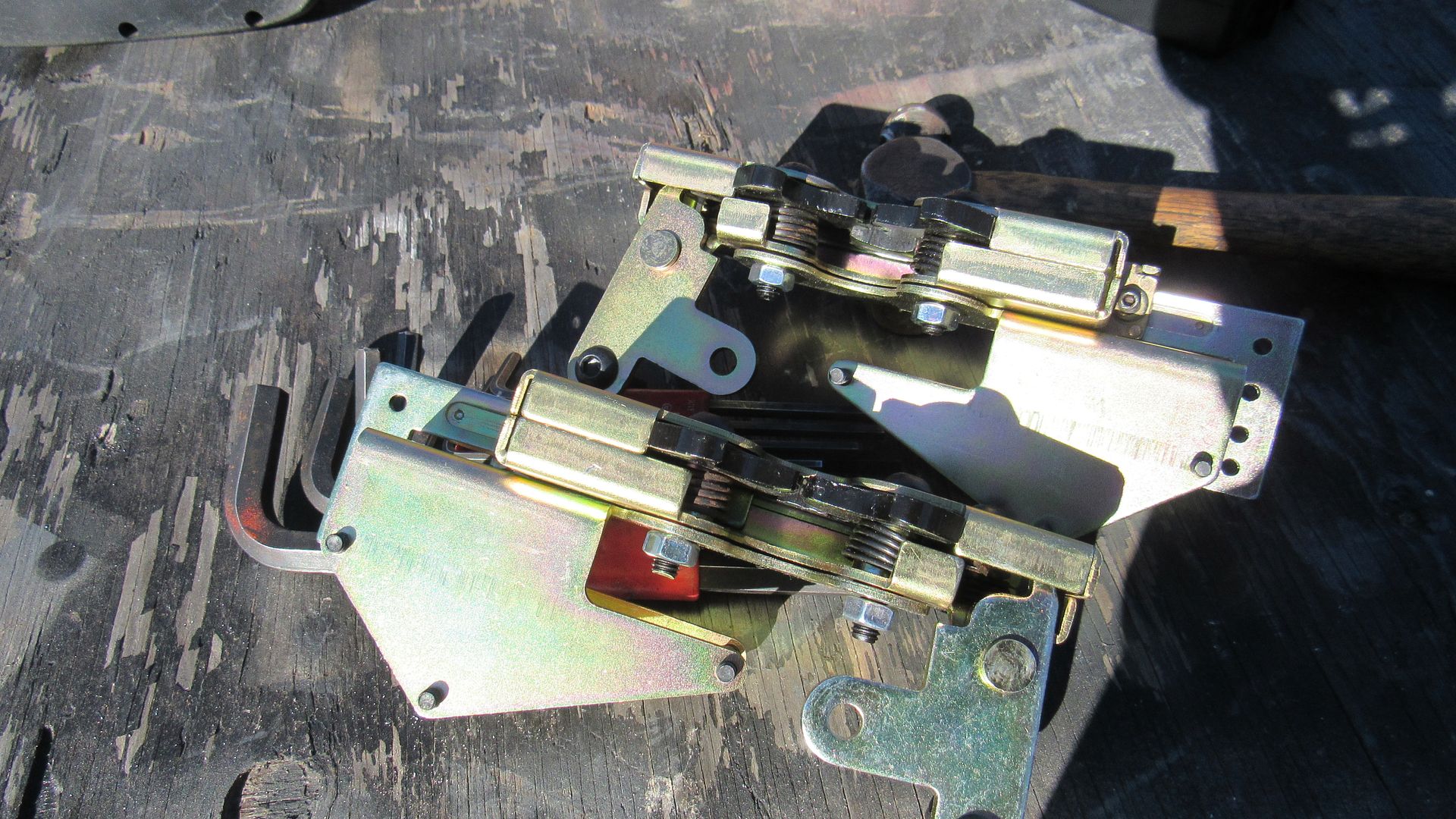

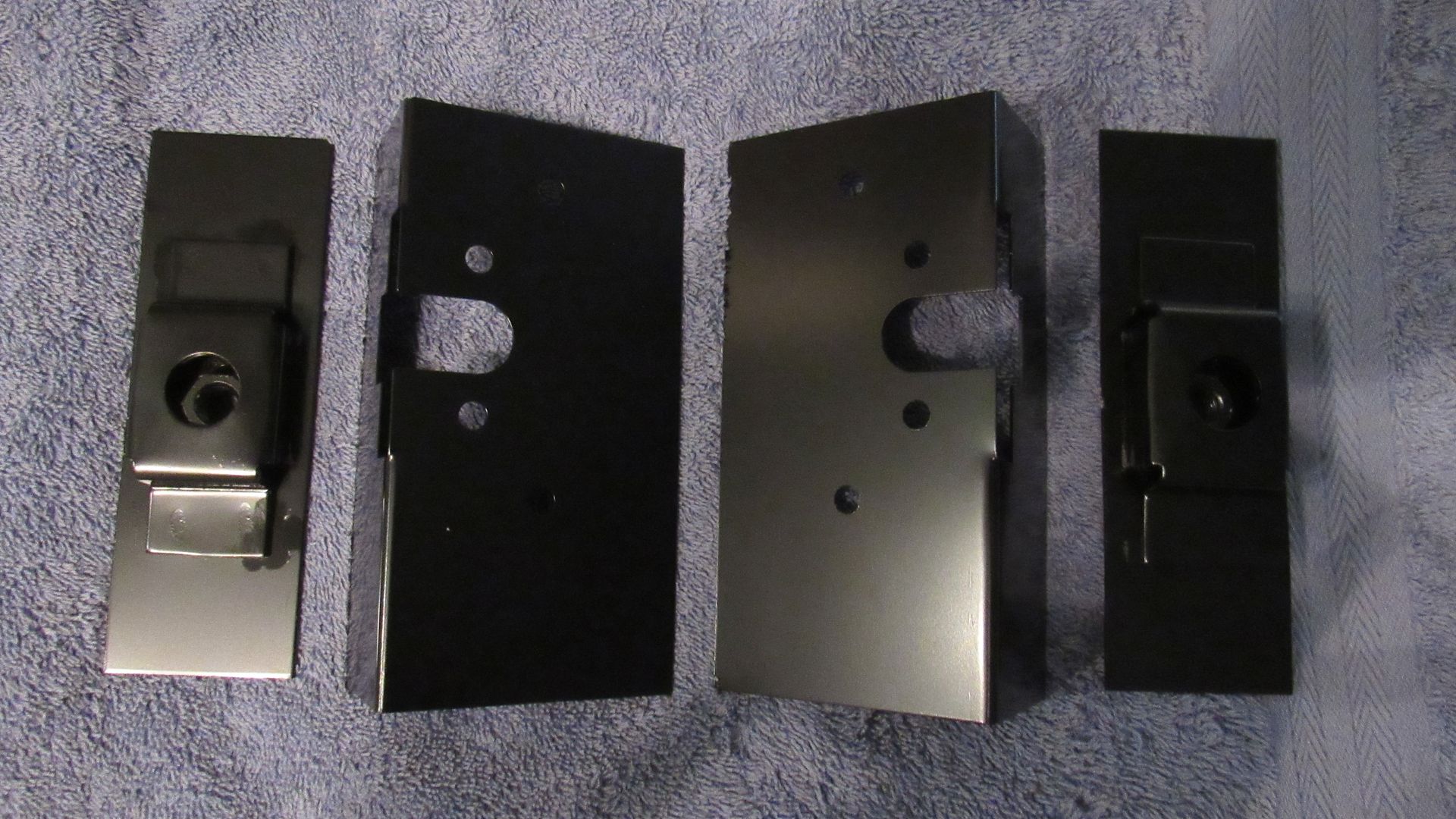

"Hope to get back up there on Monday and do some more work on it. Sure was nice to be back working on it. This is the best therapy man can buy."

Best wishes with your therapy, (medical and hobby), as I hope to finish my long languishing '55 Prez State Sedan project within the next eighteen months. Your gumption is a true inspiration...

Best wishes with your therapy, (medical and hobby), as I hope to finish my long languishing '55 Prez State Sedan project within the next eighteen months. Your gumption is a true inspiration...

Comment