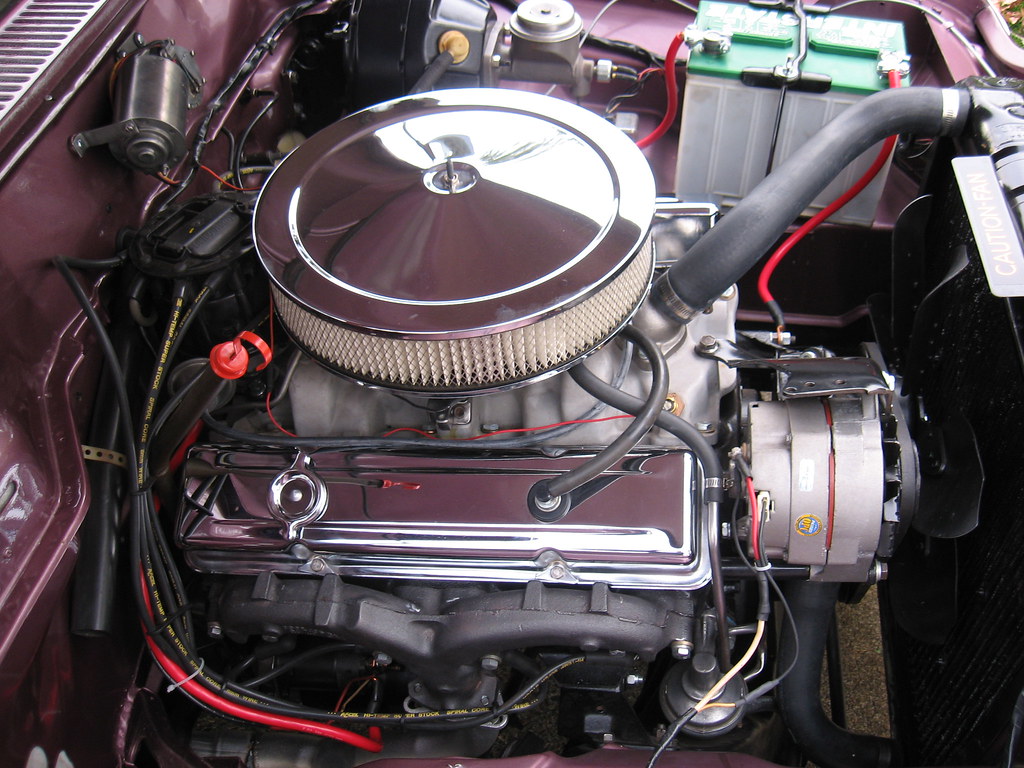

I pulled the engine (283) about 10 yrs ago, overhauled it and the auto transmission, and reinstalled them last fall. I am now nearing completion on the project and have a major problem: The fan/radiator interface is too tight. The fan would actually hit the radiator if I could get it together. While the original radiator was out during initial phase of the project, I had a local shop refurbish it and he talked me into adding some extra cores (I think that is what the heat transfer tubes are called). The shop is now gone so I cannot find out if adding the new cores would have made the radiator thicker or just wider or if the new cores made no change on the external dimensions. I do know that the radiator mounting u-shaped bracket (on the car) is fixed; there is no slack to shift the radiator frame towards the front or back. And, looking at the radiator top and bottom reservoirs, it does not appear that the fins/cores section could be shifted either. So, I have concluded that the most likely situation is that I mounted the engine/transmission too far to the front of the car.

The transmission mount has slots and I see that the bolts are setting as far to the front of the slots as possible. We installed the engine and transmission bolted together. As I remember, we installed the motor mounts first, while the transmission was supported with a jack, and then installed the transmission mounting bolts. So, I think the transmission mounting bolts just naturally fit into the slots - I don't think I moved them to the forward position in the slots on purpose, they just fit there. I cannot tell, by looking, if the motor mounts are slotted and I do not remember them being slotted when I installed them last year. If they are slotted, it might be possible to loosen the engine mounting bolts and the transmission mounting bolts and then slide the whole assemble to the rear (the drive shaft has several inches of forward/backward slop in the transmission rear housing). If that is possible and if it gives about 1/2" shift to the rear, this would give the fan some clearance.

Neither the shop manual nor the parts book show a picture of the motor mounts. I can see that the upper (engine side) of the mounts are not slotted but maybe the frame side is; I can't see. So, do any of you know if the motor mount frame side is slotted?

On the other hand, is it possible that the refurbished radiator cooling section is thicker than the original radiator? Or, maybe did the shop simply solder it too far the the rear (if that is even possible) in the radiator frame? Also, does anyone know what the minimum fan-to-radiator clearance should be?

Thanks for any information you can give.

Morgan

The transmission mount has slots and I see that the bolts are setting as far to the front of the slots as possible. We installed the engine and transmission bolted together. As I remember, we installed the motor mounts first, while the transmission was supported with a jack, and then installed the transmission mounting bolts. So, I think the transmission mounting bolts just naturally fit into the slots - I don't think I moved them to the forward position in the slots on purpose, they just fit there. I cannot tell, by looking, if the motor mounts are slotted and I do not remember them being slotted when I installed them last year. If they are slotted, it might be possible to loosen the engine mounting bolts and the transmission mounting bolts and then slide the whole assemble to the rear (the drive shaft has several inches of forward/backward slop in the transmission rear housing). If that is possible and if it gives about 1/2" shift to the rear, this would give the fan some clearance.

Neither the shop manual nor the parts book show a picture of the motor mounts. I can see that the upper (engine side) of the mounts are not slotted but maybe the frame side is; I can't see. So, do any of you know if the motor mount frame side is slotted?

On the other hand, is it possible that the refurbished radiator cooling section is thicker than the original radiator? Or, maybe did the shop simply solder it too far the the rear (if that is even possible) in the radiator frame? Also, does anyone know what the minimum fan-to-radiator clearance should be?

Thanks for any information you can give.

Morgan

Comment