My long term 52 hardtop project has come to the point where I need a brake pedal and master cylinder. I know I am not the first down this road but didn't find much on a forum search.

Impala discs are out front and Ford drums are on the back. I just have nothng to connect it all together.

My assumption for years was that I would adapt a hanging pedal and m/c from some other car. Various street rod vendors have some "universal" arrangemets that are also an option. I know of nothing purpose built for 47-52 Studebaker, however if there is I would be very happy to know about it!

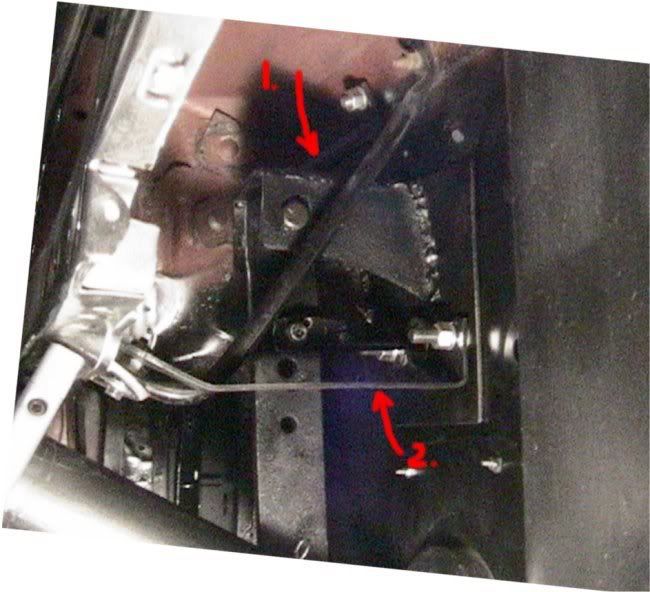

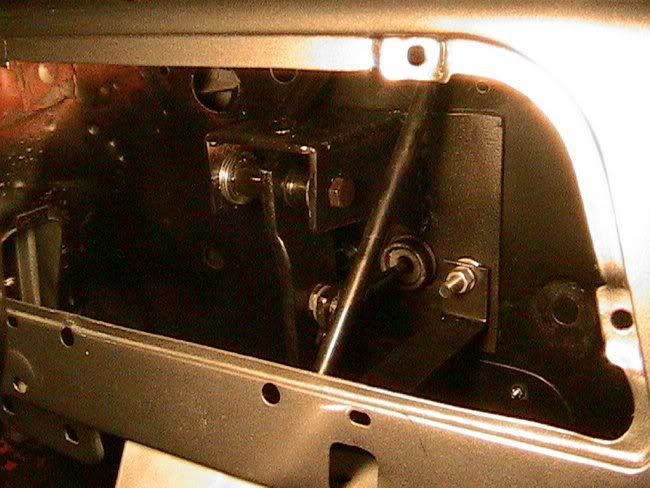

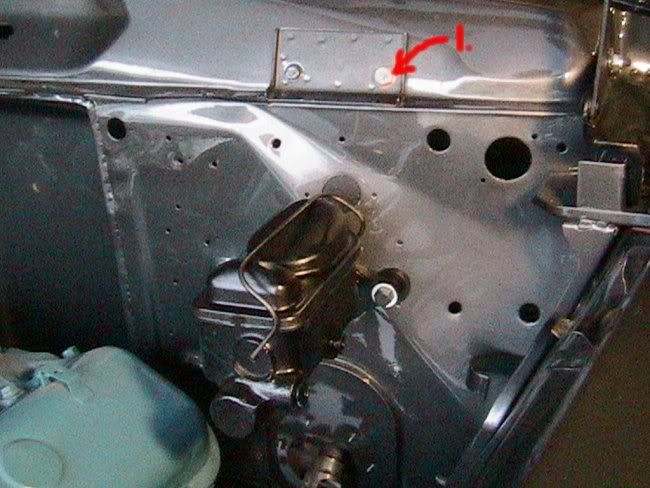

Any advice is welcome. Some might ask about using the stock pedal setup, and I will not rule it out. However I have none of these parts either - all gone. Here are some pictures of what I have to start with - a rod sticking out of the frame.

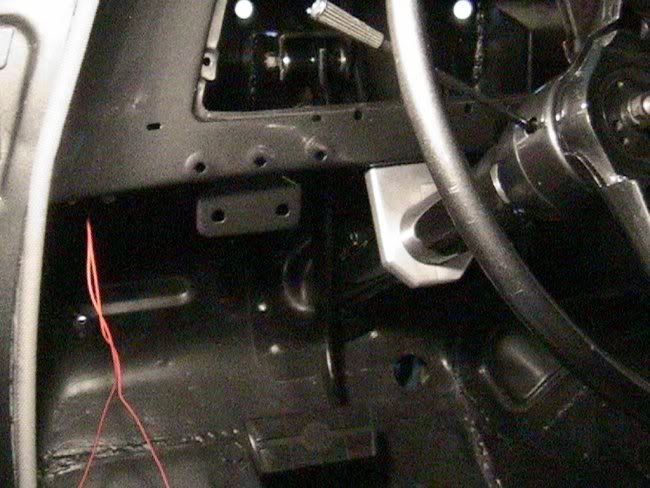

New floors are already welded in the car that have no holes for pedals. The hog troughs (hardtop) take up all the room on the outside of the frame. And my transmission mount seems to be in the way of anything on the inside of the frame like stock.

So getting back to a hanging pedal from under the dash.... Anyone have some pictures - or experience with a pedal assembly that was a smooth fit - perhaps even later model Studebaker? I have never had another and have no idea what year they went to hanging pedals.

Dan

52 hardtop

Impala discs are out front and Ford drums are on the back. I just have nothng to connect it all together.

My assumption for years was that I would adapt a hanging pedal and m/c from some other car. Various street rod vendors have some "universal" arrangemets that are also an option. I know of nothing purpose built for 47-52 Studebaker, however if there is I would be very happy to know about it!

Any advice is welcome. Some might ask about using the stock pedal setup, and I will not rule it out. However I have none of these parts either - all gone. Here are some pictures of what I have to start with - a rod sticking out of the frame.

New floors are already welded in the car that have no holes for pedals. The hog troughs (hardtop) take up all the room on the outside of the frame. And my transmission mount seems to be in the way of anything on the inside of the frame like stock.

So getting back to a hanging pedal from under the dash.... Anyone have some pictures - or experience with a pedal assembly that was a smooth fit - perhaps even later model Studebaker? I have never had another and have no idea what year they went to hanging pedals.

Dan

52 hardtop

]

]

Comment