My initial thoughts on fabing a rear mount were as simple as just narrowing the old 4-speed mount and bolting it in place. When I looked at the initial amount of work required to do that and the amount of cutting necessary, I opted for a totally new mount.

This design uses two of the original mounting holes in the frame and requires two more be drilled. The "rubber" mount this was designed for is Prothane 7-1604-BL

This is the mount I ended up with, Top View

[IMG] [/IMG]

[/IMG]

It is a combination of 1 1/2" X 3" rectangular box and a 3/16" X 1 1/4" hot rolled.

Bottom view

[IMG] [/IMG]

[/IMG]

Because I wasn't sure about the flex of the rectangular tubing, I added a couple of stiffeners between the top and bottom

[IMG] [/IMG]

[/IMG]

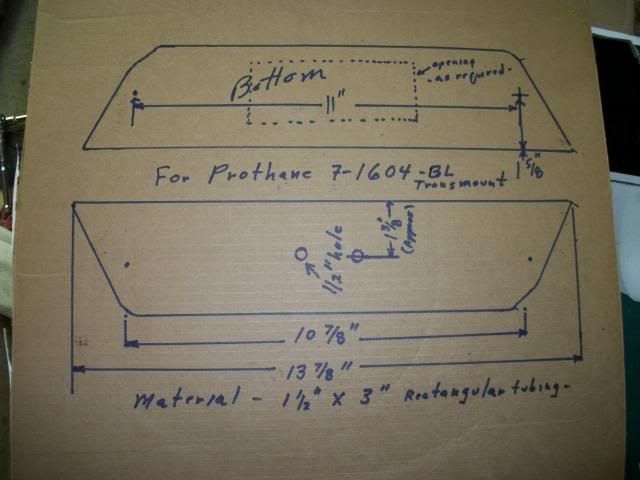

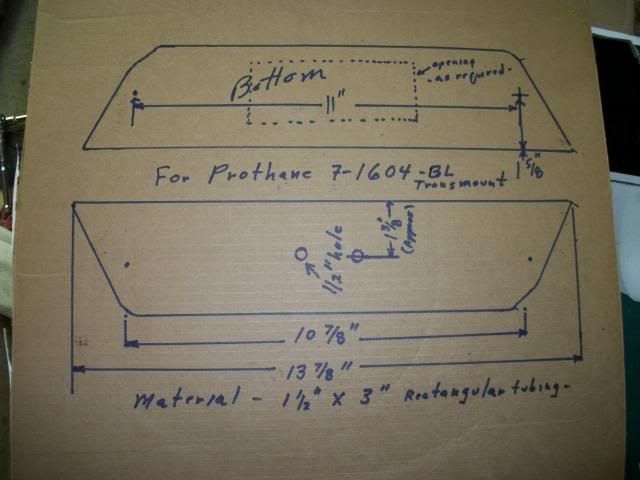

This is a simplified drawing of the mount

[IMG] [/IMG]

[/IMG]

And the mounts used

[IMG] [/IMG]

[/IMG]

From the "better lucky than good camp" is the shifter location. I fits like it was designed to be installed there. Top Shot of T56

[IMG] [/IMG]

[/IMG]

The reverse lockout solenoid "not Shown" will be a tight fit and may require a slight mod on the console side. It fits on the drivers side of the shifter housing. Because there is already an access hole cut in the tunnel, I'll probably just enlarge it allow the installation of the lockout solenoid and build a plate to cover it all.

Shifter installed

[IMG] [/IMG]

[/IMG]

The current installation sets the T56 just clear of the top of the tunnel. When the suspension in reinstalled and I get the Avanti to final ride height, I may need to massage something but the current install sets close to the original four speed location height so we shall see.

Now onto the front suspension installation and then "PAINT" WAHOO!!!! The light at the end of the tunnel may now not be a train.

Bob

This design uses two of the original mounting holes in the frame and requires two more be drilled. The "rubber" mount this was designed for is Prothane 7-1604-BL

This is the mount I ended up with, Top View

[IMG]

[/IMG]

[/IMG]It is a combination of 1 1/2" X 3" rectangular box and a 3/16" X 1 1/4" hot rolled.

Bottom view

[IMG]

[/IMG]

[/IMG]Because I wasn't sure about the flex of the rectangular tubing, I added a couple of stiffeners between the top and bottom

[IMG]

[/IMG]

[/IMG]This is a simplified drawing of the mount

[IMG]

[/IMG]

[/IMG]And the mounts used

[IMG]

[/IMG]

[/IMG] From the "better lucky than good camp" is the shifter location. I fits like it was designed to be installed there. Top Shot of T56

[IMG]

[/IMG]

[/IMG]The reverse lockout solenoid "not Shown" will be a tight fit and may require a slight mod on the console side. It fits on the drivers side of the shifter housing. Because there is already an access hole cut in the tunnel, I'll probably just enlarge it allow the installation of the lockout solenoid and build a plate to cover it all.

Shifter installed

[IMG]

[/IMG]

[/IMG] The current installation sets the T56 just clear of the top of the tunnel. When the suspension in reinstalled and I get the Avanti to final ride height, I may need to massage something but the current install sets close to the original four speed location height so we shall see.

Now onto the front suspension installation and then "PAINT" WAHOO!!!! The light at the end of the tunnel may now not be a train.

Bob

Comment