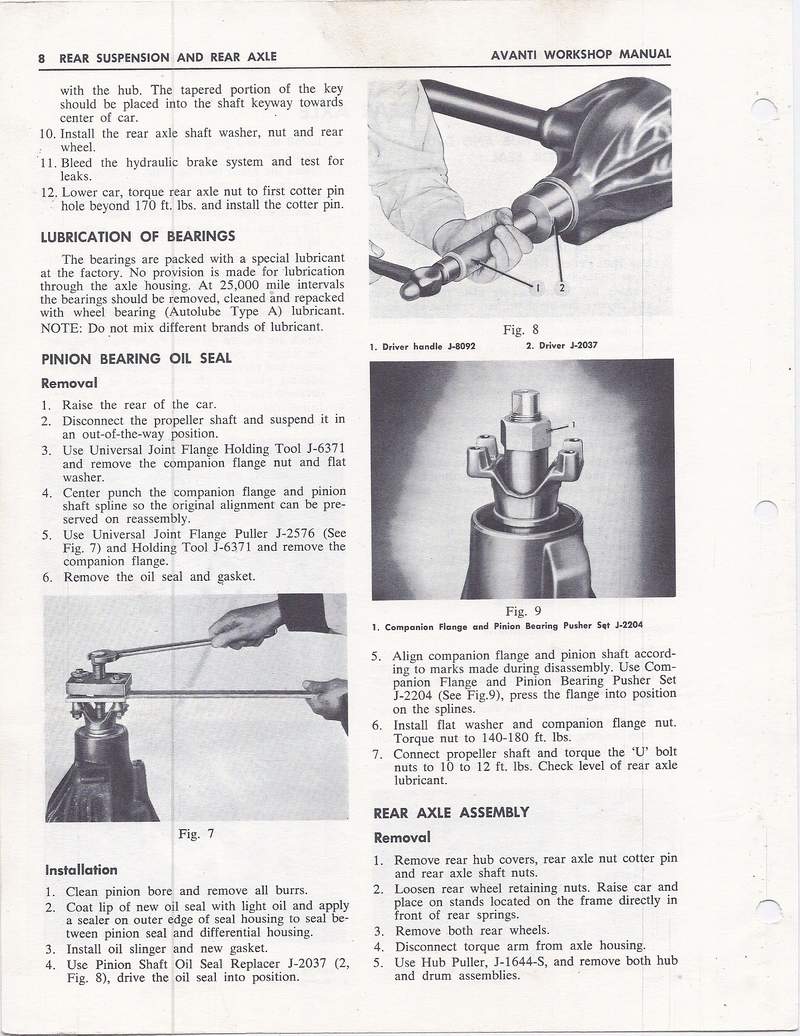

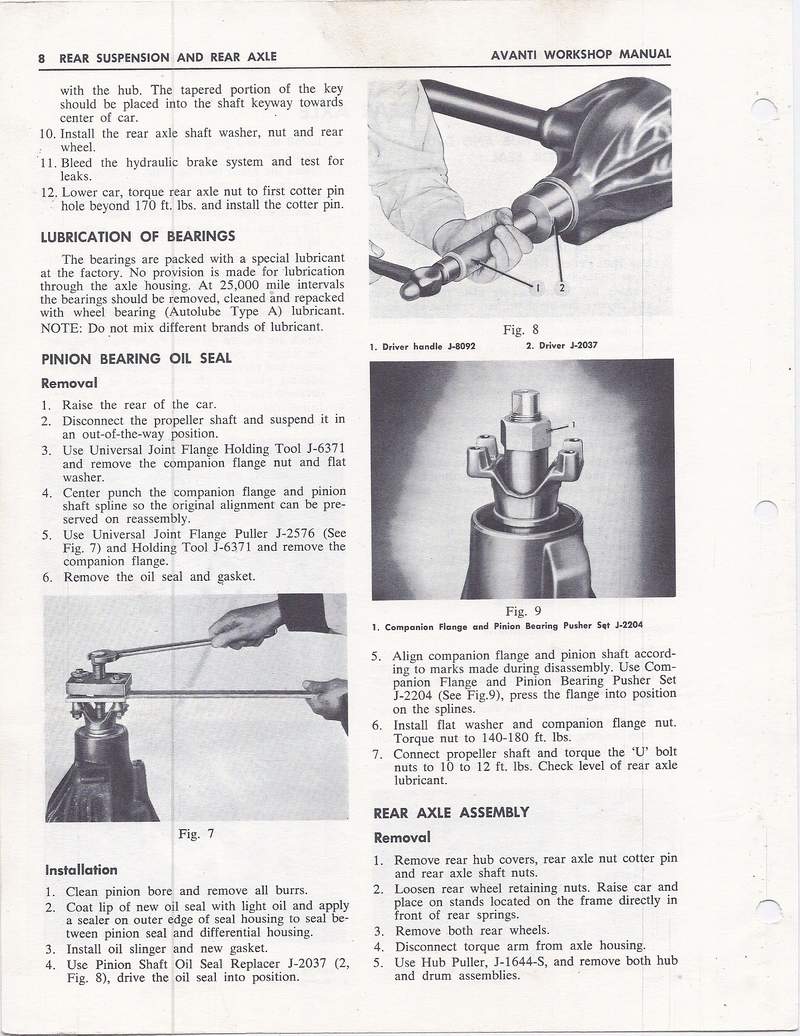

In all my years of working on my cars I have never changed a pinion seal. The discussion in the Shop Manual refers to several special tools, a Universal Joint Flange Holding Tool, J-6371, a Universal Joint Flange Puller, J-2576, a Pinion Shaft Oil Seal Replacer, J-2037, a Driver Handle, J-8092, and a Companion Flange and Pinion Bearing Pusher Set, J-2204. I certainly don't have any of these tools, but I may be able to improvise on some things. What tools do you experts use to do this job? Also, the manual mentions "apply a sealer on outer edge of seal housing to seal between pinion seal and differential housing". What kind of sealer are we talking about- silicone, gasket cement, what?

Thanks.

Thanks.

Comment