I'm at a stand-still on how to proceed with the '57 Golden Hawk project. Need to put some sheet metal in before we take the body off the chassis, but the doors have just a little sag, the floor pans have rotted out in the front, and unfortunately the holes are right next to the door pillars. Of course the rockers are rotted out and need replacing (the rest of the body is really pretty solid!

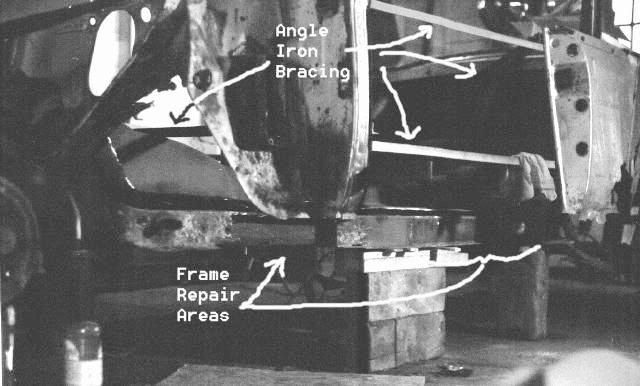

So, my problem is I'm not sure where to start, where to jack up the frame (or how much), how to go about cutting out the rockers and floor pans while maintaining squareness. Have had advice from this forum suggesting welding angle-irons across the door opening, but would sure be nice if someone who had done this with a hardtop and is in the area (I'm by Stillwater/Lake Elmo) could come out some evening or weekend and give me some first-hand tips after looking it over. I just bought myself a wire-feed welder and figured I would do as much as I can myself (after practicing a good deal on a beat-up deck-lid of the same gauge steel!) But I'm very unsure about where to try and compensate for sag by pushing something the 'other way', vs just keeping things "as they are" with cross-bracing while welding in the new rockers and floor pans patches, and trying to square things up later when I put the body back on the frame (new rubber donuts and such I assume will make some difference too). I'm also thinking I might need to replace at least one of the front body support arms (cantilevered off the frame), and this seems it could affect the doors too, if that is the sag point? Not sure if there is adjustment in the hinges where you can compensate for sag (or for inaccurate welding of the new rockers!?). Lot easier to talk it over with someone while standing and looking at it!

So, my problem is I'm not sure where to start, where to jack up the frame (or how much), how to go about cutting out the rockers and floor pans while maintaining squareness. Have had advice from this forum suggesting welding angle-irons across the door opening, but would sure be nice if someone who had done this with a hardtop and is in the area (I'm by Stillwater/Lake Elmo) could come out some evening or weekend and give me some first-hand tips after looking it over. I just bought myself a wire-feed welder and figured I would do as much as I can myself (after practicing a good deal on a beat-up deck-lid of the same gauge steel!) But I'm very unsure about where to try and compensate for sag by pushing something the 'other way', vs just keeping things "as they are" with cross-bracing while welding in the new rockers and floor pans patches, and trying to square things up later when I put the body back on the frame (new rubber donuts and such I assume will make some difference too). I'm also thinking I might need to replace at least one of the front body support arms (cantilevered off the frame), and this seems it could affect the doors too, if that is the sag point? Not sure if there is adjustment in the hinges where you can compensate for sag (or for inaccurate welding of the new rockers!?). Lot easier to talk it over with someone while standing and looking at it!

Comment