The other day I mentioned in this thread I had some odd behavior of the speedo on my '53:

http://forum.studebakerdriversclub.c...dometer-Needle

Basically, the needle was swinging up and pegging at max speed intermittantly and also slow to drop back to 0 when I stopped. I thought perhaps the drive shaft bushing in the back was worn and was allowing the rotor inside to rub on the rotating cup that the needle attaches to.

I tore into it yesterday and thought I was put up a few pix of what the inside of a speedo looks like along with some theory of operation.

I snagged this short paragraph and diagram off the net first:

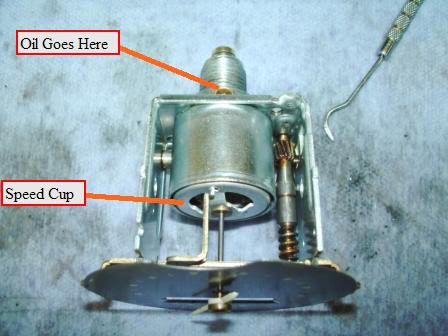

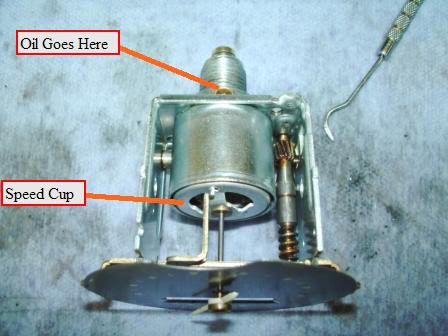

The speedo in the '53 cluster works the same way. Here's mine when sitting on the bench. The cup inside that housing is called either a drag cup or a speed cup. Its free to rotate independent of the rotor and is on the same shaft as the needle. The hair or clock spring pulls to the stop at 0. I also marked the oil fill at the back where the cable attaches. That part protrudes out the back of the cluster and should be accessable when installed for periodicly getting a drop of light oil.

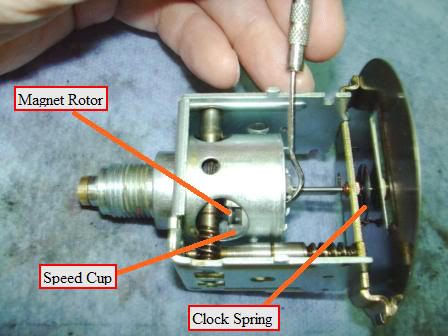

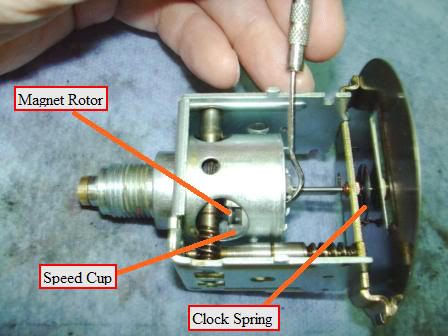

This picture shows it from the side. I pulled the speed cup up against the spring with the dental pick to a point where there is a notch in it so you can see the rotor inside there.

What happened with my speedo was my own fault. Back when I rebuilt the gauge cluster and had the speedo apart some years ago, I got a little overzealous with lubrication and put a dab of grease on all those worm gears you see that are for the odometer (I have the OD removed in these pix). The shaft that runs vertical in the lower picture has a worm drive off the main shaft under that housing just above where my arrow is pointing. Well, the grease glob from there migrated into and between the rotor and the speed cup and made sort of a "viscous clutch" and partially locked the two together!

Fortunately, it appeared nothing was damaged since the grease was fluid enough the parts could slip. I soaked the speedo in some solvent and swished it about and then blew out the grease with compressed air. Took several soakings and blowouts to get it all out so the speed cup wouldn't be dragging with the rotor.

I then oiled the bushing and put a small drop of oil on those worm gears (no grease!). I've got it sitting on the bench ready to go back in the car now and should get it in sometime in the next week. Gotta deal with a leaking water heater in the basement first

http://forum.studebakerdriversclub.c...dometer-Needle

Basically, the needle was swinging up and pegging at max speed intermittantly and also slow to drop back to 0 when I stopped. I thought perhaps the drive shaft bushing in the back was worn and was allowing the rotor inside to rub on the rotating cup that the needle attaches to.

I tore into it yesterday and thought I was put up a few pix of what the inside of a speedo looks like along with some theory of operation.

I snagged this short paragraph and diagram off the net first:

The speedo in the '53 cluster works the same way. Here's mine when sitting on the bench. The cup inside that housing is called either a drag cup or a speed cup. Its free to rotate independent of the rotor and is on the same shaft as the needle. The hair or clock spring pulls to the stop at 0. I also marked the oil fill at the back where the cable attaches. That part protrudes out the back of the cluster and should be accessable when installed for periodicly getting a drop of light oil.

This picture shows it from the side. I pulled the speed cup up against the spring with the dental pick to a point where there is a notch in it so you can see the rotor inside there.

What happened with my speedo was my own fault. Back when I rebuilt the gauge cluster and had the speedo apart some years ago, I got a little overzealous with lubrication and put a dab of grease on all those worm gears you see that are for the odometer (I have the OD removed in these pix). The shaft that runs vertical in the lower picture has a worm drive off the main shaft under that housing just above where my arrow is pointing. Well, the grease glob from there migrated into and between the rotor and the speed cup and made sort of a "viscous clutch" and partially locked the two together!

Fortunately, it appeared nothing was damaged since the grease was fluid enough the parts could slip. I soaked the speedo in some solvent and swished it about and then blew out the grease with compressed air. Took several soakings and blowouts to get it all out so the speed cup wouldn't be dragging with the rotor.

I then oiled the bushing and put a small drop of oil on those worm gears (no grease!). I've got it sitting on the bench ready to go back in the car now and should get it in sometime in the next week. Gotta deal with a leaking water heater in the basement first

Comment