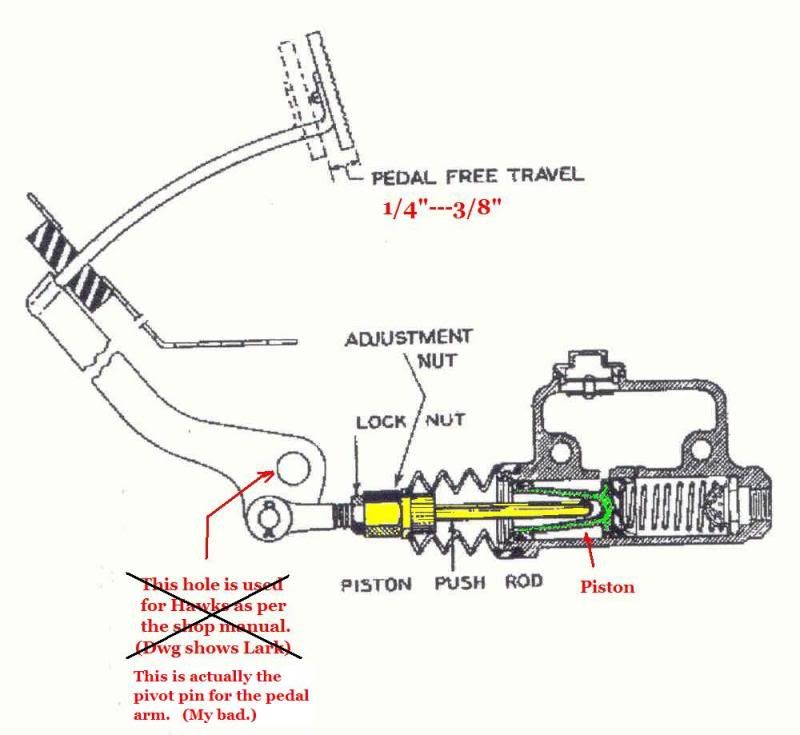

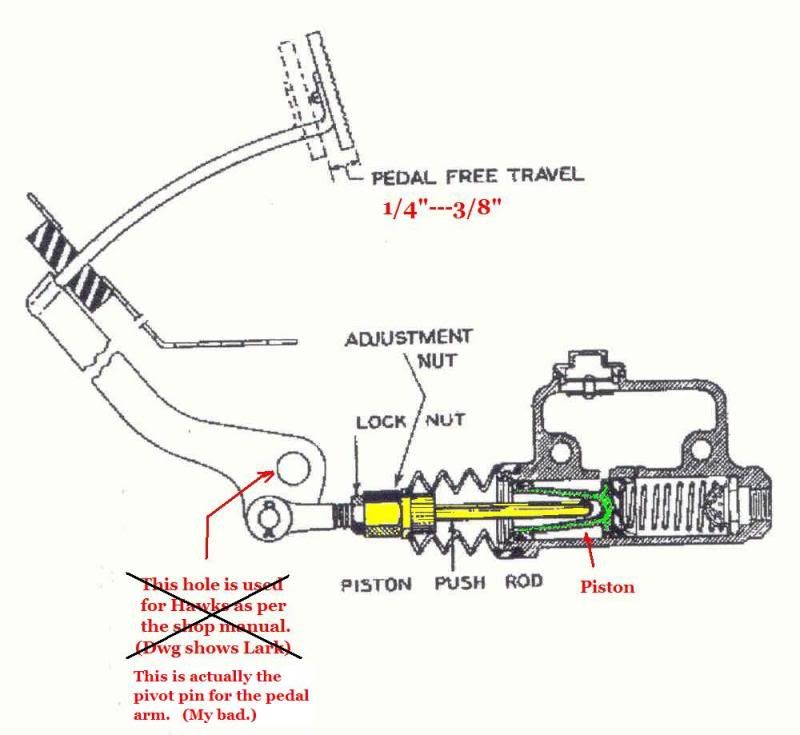

After reinstalling various components of my brake system, I'm in the home stretch. However, I have an issue. Everything is installed, and I went to adjust the brake pedal free travel. I installed the master cyl. piston push rod full forward on the clevis in order to have room to install the mc. After installing the mc, I went to adjust the brake pedal free play. The shop manual says freeplay should be 1/4"-3/8". You adjust this by turning the push rod on the clevis. My problem is that even with the pushrod adjusted all the way forward, (which should give me maximum free play), I have absolutely NO freeplay. In fact, the push rod is already applying a preload to the piston. It's as if the push rod is too long. It's a new rod, but it's the same length as the old one, but the old one was all the way forward too before I removed it. (brake pedal freeplay was rediculously huge before removal due to other issues with the mc.)

I'm tempted to cut off about 1/2" of the push rod, but would that affect the full travel if the piston? Also, I should state that the system has not yet been bled. (Master cyl was bench bled.)

I appreciate all input on what to do. Thanks, Keith

I'm tempted to cut off about 1/2" of the push rod, but would that affect the full travel if the piston? Also, I should state that the system has not yet been bled. (Master cyl was bench bled.)

I appreciate all input on what to do. Thanks, Keith

]

]

If y'all can think of anything else, please chime in.

If y'all can think of anything else, please chime in.

Comment