Its been a while since I've been on the forum, so hello every one! Thinking about doing a serpentine belt on the Stude. It's a V8. I have a machine guy lined up who can do spacers and re-machine bolt holes. Just want to know if anyone has done this if they would do it again? What parts did they use? (ford, chevy, etc) Any tips or tricks? Thanks for the help! Chris

Announcement

Collapse

No announcement yet.

Serpentine for Stude

Collapse

X

-

Yes, I've done it on a Packard V8. It can be done, but there are some caveats, because engineering a serpentine belt drive is much more difficult than it first appears. Most OEM systems use a reverse-rotation water pump. There is no such animal for the Stude V8. Since many Stude water pumps have a cast iron straight vane impeller, the pump itself will move water either way. Whether the water pump manifold will correctly direct water flow when the pump is rotating reversed is the question.

No, there aren't known combinations. When I'm working on projects such as this, I have the engine out and on a stand. Then, take a photo of the front of it with the alternator, AC, PS in the approximate locations. Mark the direction of rotation of each. When in the pick'n-pull yard, it helps to remind oneself which way everything is turning. Also, I made up a laser pointer on a straight edge this is a great help in pulley alignment. Most important is finding an OEM tensioner which will keep things tight.

Maybe you will share your progress with us.

thnx, jack vines

PackardV8PackardV8

-

Jack,

I'd love to hear about the laser pointer trick, details so I can build my on. aligning pulley is the toughest part of making brackets for alt,ac upgrades.

I had a car in the shop this weekend that I did the air install, My 79yr old Dad (who I can blame for this car sickness [8D]) takes about a 2 sec look and says "boy the belt isn't straight" I look and I look and sure enought its off by a smidgen. Laser's a good idea let me know.

Russ

quote:Originally posted by PackardV8

Yes, I've done it on a Packard V8. It can be done, but there are some caveats, because engineering a serpentine belt drive is much more difficult than it first appears. Most OEM systems use a reverse-rotation water pump. There is no such animal for the Stude V8. Since many Stude water pumps have a cast iron straight vane impeller, the pump itself will move water either way. Whether the water pump manifold will correctly direct water flow when the pump is rotating reversed is the question.

No, there aren't known combinations. When I'm working on projects such as this, I have the engine out and on a stand. Then, take a photo of the front of it with the alternator, AC, PS in the approximate locations. Mark the direction of rotation of each. When in the pick'n-pull yard, it helps to remind oneself which way everything is turning. Also, I made up a laser pointer on a straight edge this is a great help in pulley alignment. Most important is finding an OEM tensioner which will keep things tight.

Maybe you will share your progress with us.

thnx, jack vines

PackardV8

Russ Shop Foreman "Rusty Nut Garage"

53 2R6 289 5SpdOD (driver)

57 SH (project)

60 Lark VIII 2dr sd (driver)

Russ Shop Foreman \"Rusty Nut Garage\"

53 2R6 289 5SpdOD (driver)

57 SH (project)

60 Lark VIII 2dr sd (driver)

Comment

-

If anyone has ever done it or could do it on a Stude V-8,

it would have to be Jim Lange out of Effingham, IL.

His work is unbelievable. He runs the Avanti at

Bonneville and did Barlow Soper's Avanti. Contact him

at Lange Electric in Effingham. I think he may be re-

tired now but I'm sure they would know how to contact him.

Comment

-

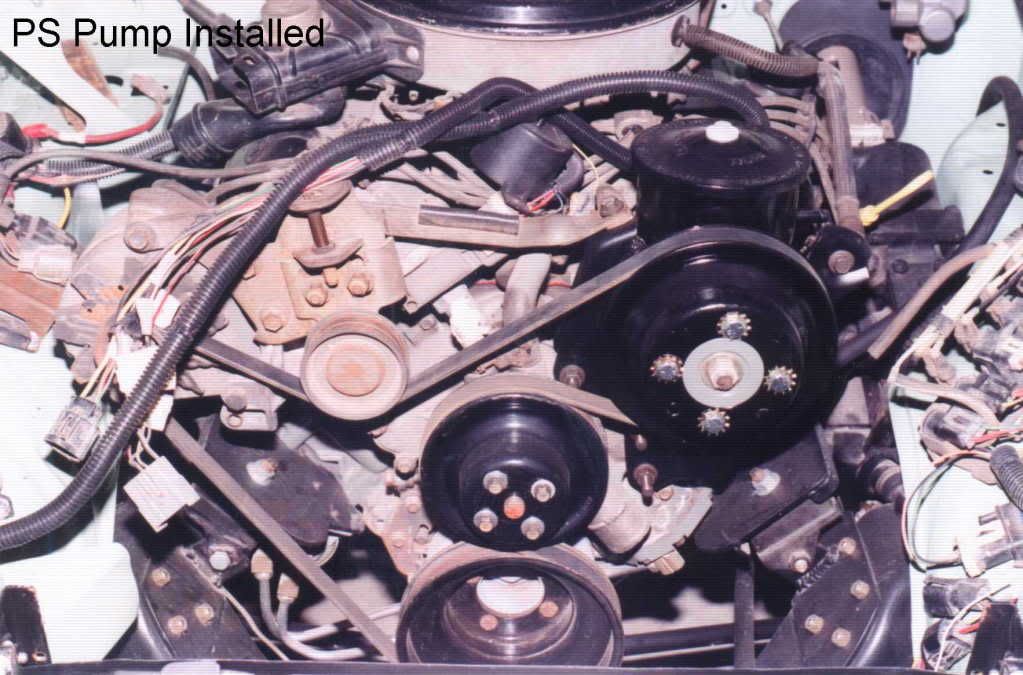

I put a Ford V6 in my '53. The engine (motor [ ]) had a serpentine belt setup on it. I also wanted to have PS in the car and secured the saginaw setup from a '57 Hawk. The problem was then how to get the '57 saginaw PS pump mounted on the V6 and with a serpentine pulley....

]) had a serpentine belt setup on it. I also wanted to have PS in the car and secured the saginaw setup from a '57 Hawk. The problem was then how to get the '57 saginaw PS pump mounted on the V6 and with a serpentine pulley....

This was not a easy problem.

The bracket part was relatively simple. I cut up the bracket the ford PS pump had been mounted to and modified it to allow the saginaw pump to bolt up to it. Some flat stock, drill press, grinder, BFH, etc, and welder were sufficient.

The pulley was not so simple. I ended up using 1/2 of a double serpentine crank pulley from a early 80s lincoln with a 302. I drilled out the spot welds to separate the 2 pulleys and used the part that had the amount of dish I needed. The pulley mounts to the pump with a custom machined hub.

In my early career I did a fair amount of drafting and mechanical design as well as machine a few prototype parts. I have access to CAD software. So, I did what I was taught to do in this situation: Measure everything and lay it out in the computer, then design a custom part to make it fit. Trial and error would also work if you have the time and machine tools readily available (and don't need to pay >$50 a hour for someone to putter with it). I don't have my own machine shop so needed to get the part right the first time. As it was, I think I was charged over $80 for a shop to make it to my drawing. Fit and works perfectly the first time though

The top picture shows the pump in its bracket with the hub adaptor. The 2nd shows the pump mounted on the engine. The former crank pulley is reversed and mimics the V belt pulley that was on the pump when it was on a stude V8. Diameter is very close to the same too. As PackardV8 suggests, this engine has a reversed rotation water pump. The pulley for it has no grooves and runs on the flat back side of the belt.

The alternator pulley should be the easiest since you can just get a alternator with one on it already from a 'yard. Maybe the crank pulley is simple too if you find one on something else with a similar enough bolt pattern to the damper and the dish and diameter are right. Plan on spending lots of time in a 'yard with measuring tools.

Jeff in ND

'53 Champion Hardtop

Jeff in ND

Comment

-

Why use a serpentine belt system? Is there some advantage?

1952 Champion Starlight w/overdrive. Searcy, Arkansas

"I may be lazy, but I'm not shiftless.""In the heart of Arkansas."

Searcy, Arkansas

1952 Commander 2 door. Really fine 259.

1952 2R pickup

Comment

Comment