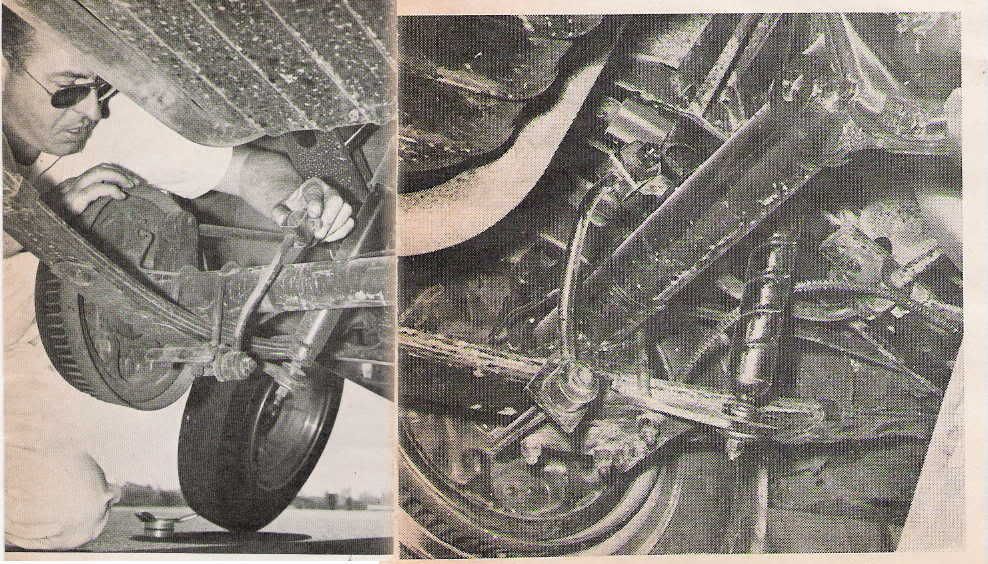

I have found PLENTY of pics of the Avanti/Hawk style but not a single one of the LARK/Sedan style with the curved radius rods. I traded some AFB and WCFB cores to Dave Theibeault for a rear sway bar and traction bar kit for the '56 Champion project and am a bit confused about exactly how to mount this traction bar kit.

I have been assured that the mounting bracket is welded in EXACTLY the same place as the HAWK/Avanti. And the frame bracket has to be mounted in the same MANNER. What confuses me is that the bar can be mounted in EITHER direction--with the "straight" part that is about 6" long at the axle end OR the frame end. Which is correct?

If anyone has a good photo of the factory LARK traction bars I would be VERY gateful if you could either post them here or email them to me.

THANK YOU!!

I have been assured that the mounting bracket is welded in EXACTLY the same place as the HAWK/Avanti. And the frame bracket has to be mounted in the same MANNER. What confuses me is that the bar can be mounted in EITHER direction--with the "straight" part that is about 6" long at the axle end OR the frame end. Which is correct?

If anyone has a good photo of the factory LARK traction bars I would be VERY gateful if you could either post them here or email them to me.

THANK YOU!!

Comment